Uncategorized

ROYAL ENFIELD COMMENCES COMMERCIAL PRODUCTION FROM THE ORAGADAM MANUFACTURING FACILITY

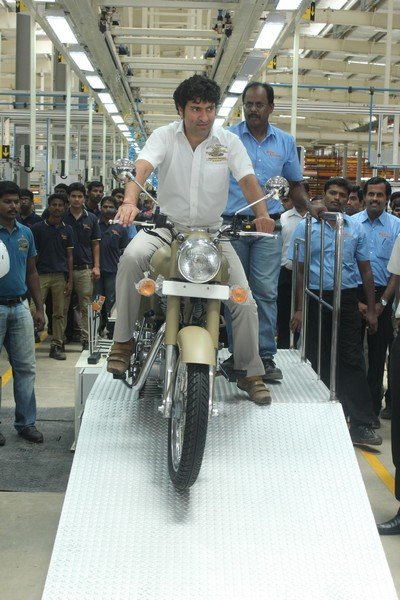

Rolling out the first motorcycle from the Oragadam plant, Mr Siddhartha Lal, MD & CEO, Eicher Motors Ltd. in the outskirts of Chennai. This is Royal Enfield’s second production facility and has been constructed at an investment of Rs 150 crore for the first phase of the facility.

Rolling out the first motorcycle from the Oragadam plant, Mr Siddhartha Lal, MD & CEO, Eicher Motors Ltd. in the outskirts of Chennai. This is Royal Enfield’s second production facility and has been constructed at an investment of Rs 150 crore for the first phase of the facility.The new 50-acre plant which is almost five times bigger from the original plat of Royal Enfield will significantly reduce waiting periods on Enfield bikes, however, even as we start commercial production today with the target of 175,000 motorcycles this year of 2013, “we have already begun working on the second phase of expansion at Oragadam, which will further increase the production capacity to 250,000 motorcycles in 2014.” said Mr. Siddharth Lal.

Last year, the company sold 1,13,000 units, and it has grown by over 50% over the last

couple of years.

Siddhartha Lal, managing director and CEO, Eicher Motors Ltd. said, “We have re-tooled many of the parts that make up our motorcycles – so that they are of exacting accuracy and finish. The ability to increase capacity fast is a crucial step for Royal Enfield towards meeting our global ambitions. While we are adding new models and new dealerships in the Indian market, we are also working on building our presence globally.�

A new CED (Cathodic Electrocoat Deposition) paint shop with a capacity of 600 motorcycles per day has been set up. Further, a robotic painting system and powder coating system have

also been employed to reduce wastage.

The new plant will help Royal Enfield to improve the quality of its motorcycles and reach out to new global markets. Built in 11 months, the Oragadam plant has been designed to optimize cost of production through relevant automation while retaining the human craftsmanship that is distinct to the iconic Royal Enfield motorcycles, the company said.

At the same time, processes such as the pin-striping continue to be done through craftsmen

who lend that special human touch to each motorcycle. The vehicle assembly line at Oragadam comes with several features such as ergonomic assembly work stations, torque controlled tools with feedback device and a capacity of producing one motorcycle a minute or over 800 per day on two shifts. Effective controls and process, right from material handling to review mechanisms, have been created on the backbone of a modern and strong IT infrastructure.

In addition, chassis dynamometers and a 1.4 kilometre test track within the factory premises allows for the motorcycles to be thoroughly tested before they are dispatched for customers.

The second plant would initially begin with the production of Desert Storm and Thunderbird vehicles. By the end of the year, the company expected to produce the entire range, including the Bullet and Classic, he said. Construction of the facility began in February 2012. Trial production began in January this year. Royal Enfield already has a plant in Tiruvottriyur near here. Pointing out that the U.S. was the largest export market for Royal Enfield, Mr. Lal said that last year the company shipped about 3,500 units to the country out of the total 1,13,000 units sold.

The Oragadam facility has been built with sustainability in mind from the very beginning of the design stage with several initiatives such as reduction of effluent generation at source and zero liquid discharge system of treatment. In addition conservation of resources such as electricity, water and fuel has been given top priority. Even during the construction stage, the green concept was applied such as using soil from within the site for filling, as well as using the ideal quantities of steel, concrete and cement. The focus was also on creating efficient work spaces, equipment and utilities and hence effective use of natural, diffused lighting, natural air flow inside plant and 25% of wooded area have been ensured.